Hazardous Area Instrumentation. Training & Certification

Learn everything about Hazardous Area Instrumentation in one easy online learning course! Includes the following:

- Area Classification, Material & Temperature classification

- Understanding IEC & NFPA/NEC Standards, ATEX, IEC-Ex

- Understand how Explosionproof, Increased Safety, Intrinsic Safety, Pressurization, Purging, Non incendive and other techniques work

- Learn about markings, inspections, maintenance

- Fieldbus in Hazardous areas

* Easy Self Paced , structured eLearning Course, access online 24/7

The Abhisam Hazardous Area Instrumentation e-learning course was the first of its kind when launched in the year 2004. Now after 14 years on, with several revisions and updations, it is the best learning resource on the topic that you can find anywhere. Used by professionals in many industries such as Oil and Gas, Chemicals, Mining, Power Generation, Shipping, Industrial Automation, Engineering Consultants and governmental organizations, it remains the premier training course for this subject all over the world!

* Understand Hazardous Area Concepts easily via Animations and Simulations, videos

A picture is worth a thousand words and an animation is worth a thousand pictures! Learn all important aspects of hazardous area instruments via engaging animated nuggets that show you how explosionproof enclosures work, how threaded joints and flanged joints work to protect enclosures, how intrinsic safety barriers and isolators work and many more!

* Real Life examples including photos from plants and facilities

When you get the Abhisam e-learning course, you are not buying some outdated textbook or pdf, you are getting decades of experience of hazardous area experts who have spent their lifetimes in industry. So the examples that are used to explain and photos are from actual industrial facilities and devices.

* Save on Travel and Stay costs. Learn at your own pace.

Getting this course means not having to travel somewhere to learn about the topic. Learn at your own pace, maybe just a hour everyday or whenever you feel like it. No need to travel to a faraway place and spend time and money on travel or stay. Learn in the comfort of your own office or home, or even on the beach! We make geography, history.

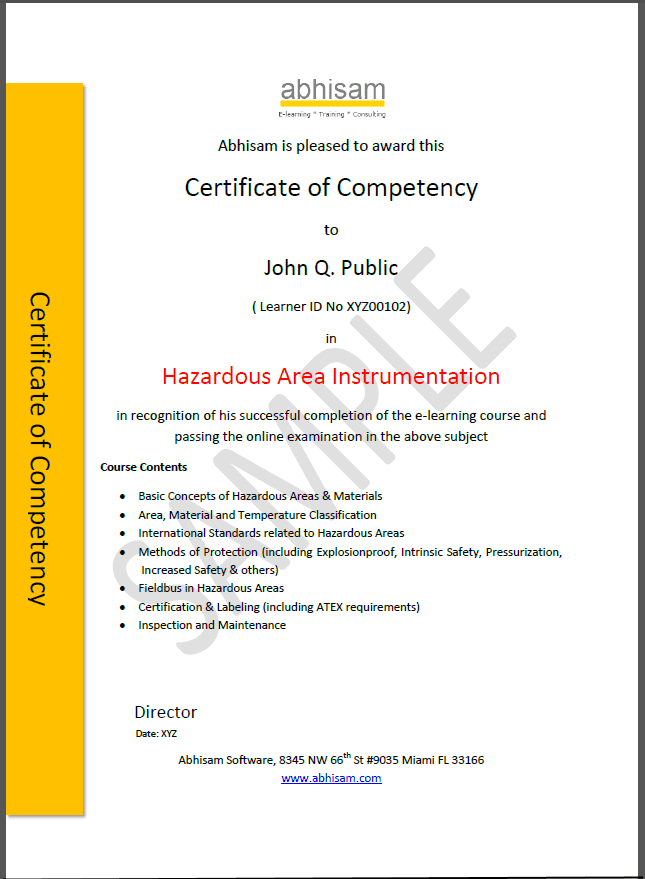

* Get Certified as a Hazardous Area Professional (earn a Certificate with lifelong validity and an electronic Badge)

We enable you to earn a Certificate of Competency in Hazardous Area Instrumentation, with lifetime validity, at no additional charge! Also get an electronic Badge that can be displayed online on places such as LinkedIn or Facebook, to let your peers, bosses and clients (present and future) about your skills and achievements.

Key Benefits of the Course

- Self Paced Course, learn at your own speed, whenever you wish

- Learn from home, office or anywhere else

- Access from any device PC/laptop/Mac/Tablet-no restrictions

- Includes Online Exam and Certification

- Prove your competency by displaying your electronic badge online on social media

- Full fledged e-learning course- Its not a video of a guy speaking or a pdf or a PPT

- Learn from Real life situations and case studies

Get Certified as a Professional! Earn an electronic badge that you can display online.

Customer Feedback

We are the Gulf of Suez Petroleum Company, one of the major Oil & Gas production companies in EGYPT. I would like to express our good impression on such course. It is one of the most comprehensive, information rich and fun at the same time regarding Hazard area classification and its equipment installation practice.

Best regards for the abhisam company!

Instrumentation Department

GUPCO, Egypt

Learners from Marquee Companies

This course is the oldest e-learning course in Hazardous Area Instrumentation worldwide! Updated continuosly, this is now the fifth version since it was first introduced in 2003. Engineers and Managers from marquee companies have learned via this course, only a few examples are shown below

The course has real life examples from actual projects and operating plants/ installations that give you a step by step method to do work related to Hazardous Areas. For example, here’s an example from the section on Intrinsic Safety.

Example: This example is given as a guideline, to demonstrate how an Intrinsically Safe loop is designed. We have to implement an open loop (tag No TI-101) for temperature measurement, consisting of a thermocouple and a temperature transmitter, using the principles of Intrinsic Safety. The Safe area equipment which will be connected to this is a DCS. The Thermocouple is mounted in a thermowell on a process reactor. This reactor is located in a hazardous area classified as Zone 1, Group II A, T4.

Do you know how to do this? Learn it in the course.

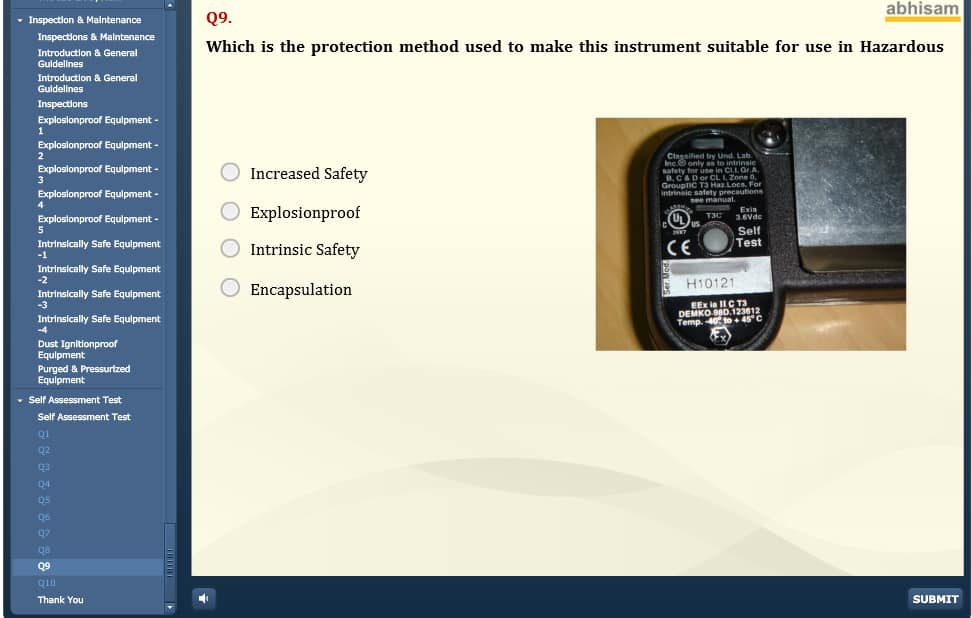

After you complete all the modules in the training program, you can take the Self Assessment Test which enables you to gauge your own understanding of the subject. This also acts as a mock test, before you take the online Certification Exam. Here’s a screenshot of one of the Questions.

Are you an employer? (Manufacturing or Engineering Consulting company or Industrial Automation supplier or a Contracting Company)

You know that it’s YOUR responsibility to train your employees… So what are your options?

You could ignore training requirements opening yourself up to MASSIVE liabilities if your employees are injured or killed on the job or you lose some of your plant assets to fires and explosions…You could be out of business… Or even worse… Almost instantaneously…

You could pay thousands of dollars to send employees to live training workshops, or several hundreds of dollars on study guides, books and courses…

OR you can buy this interactive training course that has proven to be the fastest and easiest way for employees to learn… And RETAIN… Information about this important subject.

We make the learning process fun and easy. Our e-learning course is full of graphics and animations/ simulations that are entertaining to watch, incredibly simple to understand, and provide the fastest and easiest way to learn everything you need to know about this complex subject..when you go through the program, Hazardous Area Instrumentation will no longer appear complex.

We’ll Teach You Everything You Need To Know regarding this… And We’ll Make It More Fun To Learn, Easier To Understand, And More Cost Effective Than Any Other Training Solution… Guaranteed!

Special Enterprise Pricing for companies! Scroll below to see options.

Just for your information, here are some of the accidents in the news…reported and investigated by the Chemical Safety Board. Directly related to lack of knowledge about hazardous areas.

Choose from any of the versions.

Scroll below to see complete contents.

Standard

For one learner-

Course Duration: 16 hours of self paced learning (Earn 16 PDH)

-

Access the course online 24/7 via any device for one year

-

Exam & Certification for one learner

-

Lifelong Valid Certificate

Professional

For one learner-

Everything in Standard plus

-

Access the course for 3 years

Get Access to all Abhisam Trial courses, including this Hazardous Area Instrumentation course for $7. You will NOT be billed automatically after trial ends.

Note: Trial versions of courses have only the first few modules viewable.

Table of Contents

Introduction to Hazardous Areas

History related to Mines

Miners Safety Lamp

Flammable Liquids, Gases & Vapors

Fire Triangle

Explosive Limits

Hazardous Atmosphere

Effects of Temperature & Pressure

Ignition Energy

Flash Point

Autoignition Temperature

Dust Hazards

Explosion Pentagon

Why do we classify hazardous areas?

More about classification

Different Types of Standards

Standards Bodies -IEC

Standards Bodies – NFPA

Area Classification for Gases & Vapors (IEC)

Area Classification for Gases (IEC)

Area Classification for Dust atmospheres (IEC)

Area Classification for Dusts (IEC)

Material Classification (IEC)

Material Classification (IEC) – Examples

MESG (Maximum Experimental Safe Gap)

Minimum Ignition Current (MIC)

MIC Ratio

Temperature Classification (IEC)

Classification of Hazardous Locations (American System)

Material Classification for Gases & Vapors (North American System)

Classification of Gas Groups (North American System)

Comparison between IEC and the North American System

Article 505 of the National Electrical Code

Area Classification of Dusts (North American)

Dust Groups (North American)

Area Classification for Fibers and Flyings (North American)

Temperature Classification (American System)

Summary-IEC

Summary-NEC

Step by step Area Classification for Gases & Vapors

Pitfalls in the Classification Process

Area Classification for Dusts

Example of Area Classification

Introduction to ATEX

The ATEX Directives

The ATEX Directive 94/9/EC-1

The ATEX Directive 94/9/EC-2

ATEX Equipment and Categories

ATEX suitability table

ATEX Directive 1999/92/EC-1

ATEX Directive 1999/92/EC-2

ATEX Directive 1999/92/EC (contd)-3

ATEX 2016 Updates

Integrated Explosion Protection

Non Electrical Ignition

Traceablity

ATEX Exclusions

Overview of Protection Philosophy

Explosionproof Method (IEC Code Ex-d)

Explosionproof Fundamentals

Explosionproof Working

Pressure development in an enclosure

Pressure Piling

Explosionproof MESG

Standards & Practices for Explosionproofing

Explosionproof Seals

Explosionproof IEC

Dust Ignition Proof

Explosionproof Advantages

Explosionproof Disadvantages

Intrinsic Safety (IEC Code Ex-i)

Intrinsic Safety Basics

Intrinsic Safety – Resistive Circuits

Intrinsic Safety – Inductive circuits

Intrinsic Safety Capacitive

Minimum Ignition Current (MIC)

Resistive Circuit Curves

Curves for Gas Group IIC

Capacitive Circuit Curves

Inductive Circuit Curves

Intrinsic Safety – Simple Apparatus

Intrinsic Safety Apparatus

Intrinsic Safety Barriers – Diodes

Intrinsic Safety Barriers – Zener Diodes

Ordinary Diode Curves

Zener Diode Curves

Functioning of a safety barrier

Safety Description of barriers

Zener Barrier example

Zener Barriers – Earthing

Isolators

Isolator details

Infallible Components

Entity Concept

Cable Parameters and L/R ratio

Ex-ia, Ex-ib, Ex-ic

Intrinsic Safety Parameters – 1

Matching of IS parameters

Designing an Intrinsically Safe loop – example

Designing an IS loop (contd)

Intrinsic Safety – Advantages & Disadvantages

Pressurization & Purging

Types of pressurization

Pressurization Interlocks

Purging Types X, Y and Z

IEC Types Ex-px, Ex-py and Ex-pz

Pressurization – Advantages & Disadvantages

Increased Safety – Introduction

Increased Safety – Construction

Creepage and Clearances

Overloads

Increased Safety – Advantages & Disadvantages

Nonincendive equipment

Non Arcing Equipment

Differences between Ex-nA and Ex-nL

Nonincendive Equipment – Advantages & Disadvantages

Encapsulation

Encapsulation

Powder Filling & Oil Immersion

IEC Equipment Protection Level

IEC Protection Methods Table – Gas/Vapor

IEC Protection Methods Table – Dusts

Weather Protection

NEMA Codes – Indoor Non hazardous locations

NEMA Codes – Outdoor non hazardous locations

NEMA Rating for Hazardous Locations

Ingress Protection Codes

IP Codes Chart

Comparison between IP and NEMA

Fieldbus in Hazardous Areas

Using traditional explosionproof methods

Fieldbus using Intrinsic Safety

Fieldbus Entity Calculation Example

FISCO

FISCO Topology

FISCO Conditions

FISCO Advantages

FNICO

FNICO with repeaters

FNICO and Ex-ic

Field Barriers & High Energy Trunks

Introduction

Certification Bodies

Marking & Labeling

ATEX Marking

Marking & Labeling -Example

Testing

Hexagon Ex and CE Marks

Marking & Labeling -Example

The IEC Ex System

Introduction & General Guidelines

Inspections

Explosionproof Equipment

Intrinsically Safe Equipment

Dust Ignitionproof Equipment

Purged & Pressurized Equipment

The Self Assessment Test is a practice mock test that helps you prepare for the Hazardous Area certification exam

Just get this Hazardous Area Instrumentation training course today for a much lesser price than any other course out there

No other course (Classroom or e-learning or software or online or video or any other) includes all of these modules in one course!

Can I not get this information free from elsewhere?

There is a myth “Just Google it”

Unfortunately it is not true. If you Google for it you are likely to get a large number of Hazardous Area Instrumentation related articles, videos, ebooks and other material. You may also get a lot of information about explosionproof instruments, intrinsically safe instruments, safety barriers, galvanic isolators, purged panels and mich more.

However, none of these will teach you

How does an Explosionproof enclosure actually work? (Find out in our animations)

How does it contain the explosion?

How much pressure gets developed inside?

Why are there different criteria for Group IIA, IIB and IIC instruments?

What does the ATEX mark mean?

What is the difference between flange covers and screwed ones? What do you mean by flamepath?

How do you design an Instrument loop using Intrinsically Safe instruments? How do you match the parameters of the zener barrier or isolator to the instrument?

What is the importance of cables?

You will find all your questions answered here and many with animations so that you can easily grasp complex concepts.

Also, Earn a Certificate of Competency in Hazardous Area Instrumentation, when you pass the associated exam and also get an electronic badge that can be displayed online on places such as LinkedIn. Get Noticed as an Expert!

Can I not simply buy a book? That will be much cheaper!

Of course, you could always pass this up and decide to go for buy a book on this topic,

but,

remember that there are some disadvantages with this approach

a) The first is that not a single book is available on the market, that covers all the topics that you need to know. On the other hand, there are a lot of things in every book, that you can safely skip, without missing anything.

b) Some of these books may be outdated and obsolete as the standards keep on getting updated whereas the book remains as it is.

c) Watching an animated simulation makes you grasp a concept much faster than merely reading about it.

and Finally,

d) Nobody gives you a certificate if you simply read a book.

What does the $7 trial include?

The $7 trial includes trial access to ALL the courses in the Abhisam Catalog for a limited time.

After the trial is over you can choose to either buy an individual course OR subscribe to the GOLD or PLATINUM membership plans. Your card will not be billed automatically.

Which versions are available?

This course is available as either stand alone (select the Standard version above), Professional, or as part of the Abhisam GOLD membership level.

The Standard version allows you to access the course online from any device (PC/tablet/smartphone) that has an internet connection and a browser that supports HTML 5 (such as Mozilla Firefox, Google Chrome, Internet Explorer, Microsoft Edge, Opera, etc). You can access the course for a period of one year, within which you need to take the exam to earn a Certificate (electronic). You will also earn an electronic badge that can be displayed online on LinkedIn and similar portals.

The Professional version allows you to access the course online for 3 years from any device (PC/tablet/smartphone) that has an internet connection and a browser that supports HTML 5 (such as Mozilla Firefox, Google Chrome, Internet Explorer, Microsoft Edge, Opera, etc). You can access the course for a period of three years, within which you need to take the exam to earn a Certificate (electronic). You will also earn an electronic badge that can be displayed online on LinkedIn and similar portals.

The content in the Standard and Professional versions is the same.

What is the Abhisam GOLD membership?

When you subscribe to the Abhisam GOLD membership, you get access to all the courses in the Abhisam Catalog, by paying just one low monthly subscription. You can also get a free certification exam every month. If you are interested in taking a bunch of courses, then the GOLD membership gives you an affordable plan to do this. This is available to individuals only.

What is the Abhisam Platinum membership?

This is meant for organizations with multiple learners. When you subscribe to the Abhisam Platinum membership, your learners get access to all the courses in the Abhisam Catalog, by paying just one low Enterprise yearly subscription. You can also get a free certification exam every month. Additionally you also get a Dashboard where your Training Manager can see the progress of the learners, such as learner module completion, login times, test scores, etc.

Other Hazardous Area Courses

Hazardous Area Classification with certification

The only affordable and easy course on hazardous area classification!

Learn from real life examples, how to classify hazardous areas (includes both IEC and NFPA/NEC), calculate the extent of hazardous areas, ventilation considerations, make hazardous area classification drawings and more!

Includes a free Certificate of Competency and an electronic badge when you pass the exam.

FREE Hazardous Area Course!

Take this FREE Hazardous Areas training course and learn the basics online at your own pace.

Covers concepts of fire, explosion, LEL, UEL, Flash Point and other fundamentals.

Optional (paid) Certificate available.

Questions?

Contact Us by filling the form below OR call us OR email