In the next few minutes of reading this you will understand the difference between IEC 61511 and IEC 61508.

What is IEC 61511?

IEC 61511 is the process industry standard for Functional Safety and Safety Instrumented Systems. This standard has been developed by the International Electrotechnical Commission and is used globally.

Process industries are those industries that handle bulk materials (rather than discrete parts) and include the Oil & Gas production, Petroleum refining, Chemicals manufacturing industries and similar, where large bulk quantities of materials are processed. The industries in this sector are different from those in the discrete parts manufacturing domain such as a factory making say, nuts and bolts for example, or one that is an automobile assembly line.

What is IEC 61508?

IEC 61508 is the main standard for Functional Safety, that is the basis for all other industry specific Functional Safety Standards, such as IEC 61511 for the process industry sector, IEC 62061 for the Machinery sector and so on. Thus one can say that the version of IEC 61508 which is used in the process industries is IEC 61511.

What is the relationship between IEC 61511 and IEC 61508?

Both standards have Safety Instrumented Systems requirements that must be met in order to be compliant to the respective standard.

When designing, building, installing, maintaining, repairing, modifying or carrying out proof testing for Safety Instrumented Systems (SIS for short) used in the Process industry, we refer to IEC 61511. However, the devices used in building the SIS have to be compliant to IEC 61508 individually. Also if our Safety Instrumented Function (SIF) needs to be SIL 4, then IEC 61511 directs us to refer to IEC 61508 to build it.

The first step is to evaluate whether we really need SIL 4 or we can reduce the risk by other means, so that the SIF need not be SIL 4 but can be for example SIL 3, but if we find we really need SIL 4 then we need to refer to IEC 61508.

Asset Owners and System Integrators follow IEC 61511

Thus if you are an asset owner who has a Safety Instrumented System in their plant, used for ensuring a safe shutdown of the plant, then this system needs to be compliant to IEC 61511 (or ISA S84 in the United States-both are textually almost the same standard), but the individual devices that make up the SIS (such as the sensors, transmitters, logic solvers, final control elements like actuators and valves, etc) need to be compliant to IEC 61508. Thus in short one has to gather individual components/devices that all conform to IEC 61508 and then use the standard IEC 61511 to actually build the system. Read more on SIS requirements here

The organization has to be capable of following the Functional Safety management clauses in IEC 61511 in order to maintain the SIS properly.

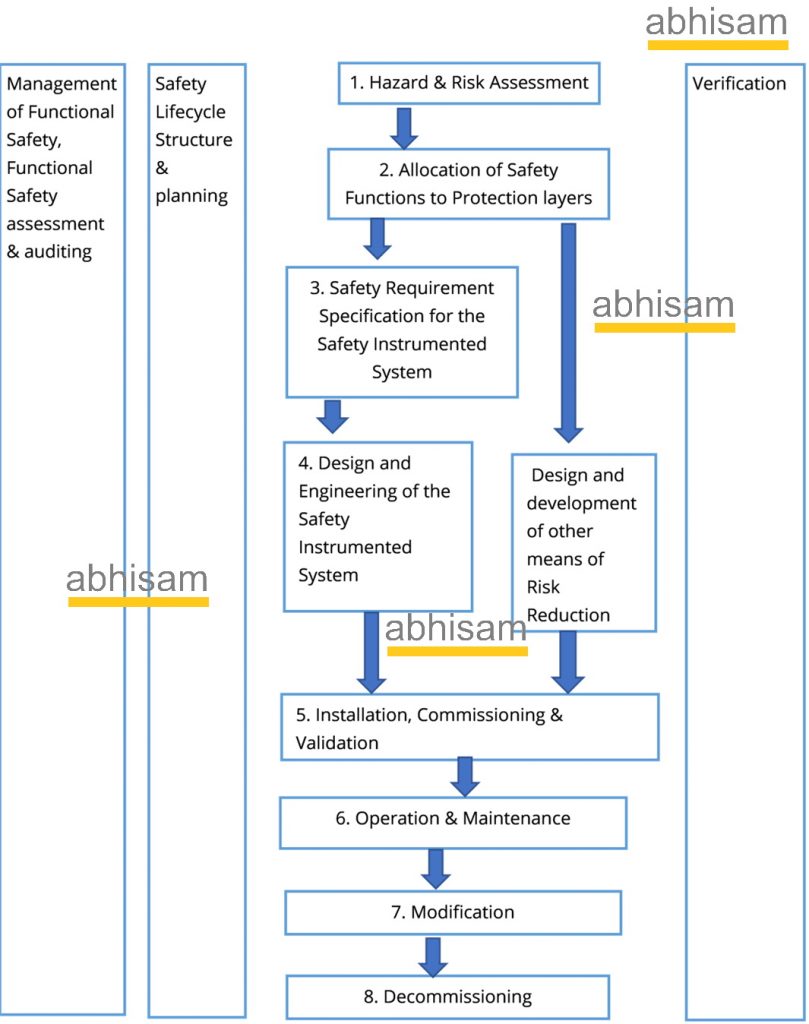

Here is a Safety Lifecycle based on the one given in IEC 61511.

—— Download this excellent free ebook on Functional Safety & SIL today (Guide continues below) ——

Automation vendors follow IEC 61508

If you are an automation vendor (also known as an IACS vendor where IACS stands for Instrumentation & Automation Control System), who manufactures devices like sensors, transmitters, logic solvers (referred to popularly as Safety PLCs), etc that will be used in a Safety Instrumented System, then your devices have to be designed and built according to IEC 61508. In fact your entire organization has to be capable of meeting the requirements of IEC 61508.

Note that the Safety Lifecycle followed by an automation vendor will be as per IEC 61508, which is different from the one given above.

However automation vendors should also know how the IEC 61511 lifecycle works, as they will be working closely with the asset owner (who owns the Oilfield or Chemical plant) and their representatives (such as EPC contractors and design engineers). Read More on Safety Instrumented Systems IEC 61511 here.

Where can I learn more? How can I get certified in Functional Safety and SIS?

Simply take the Abhisam Safety Instrumented Systems training course to learn about IEC 61508 and IEC 61511 in detail. Everything is explained via easy animations, simulations, videos, real life examples and exercises that makes learning this difficult subject very easy. Also if you take and pass the associated exam (at no additional cost) you also earn the title of a Functional Safety Professional/SIS Professional with a certificate that has lifelong validity.