Safety Instrumented Systems

What is a Safety Instrumented System?

Safety Instrumented Systems keep plants and equipment safe from unmwanted incidents. If you are an Industrial automation or a Functional Safety professional, it is important for you to know how these systems work and also get yourself certified, as a Safety Instrumented Systems Professional.

What are Safety Instrumented Systems?

Safety Instrumented Systems are a special class of industrial automation systems that are used to implement safety functions to protect assets, people and the environment. In recent years, there have been extensive studies on the best ways of making our process plants safer and the conclusion is, that by just doing one thing right, which is -increasing the reliability of the Safety Critical systems in a manufacturing plant. Taking this Abhisam Safety Instrumented Systems training course is by far the fastest and easiest way of learning about this subject online and getting certified.

Key Benefits of the Course

- Self Paced Course, learn at your own speed, whenever you wish

- Learn from home, office or anywhere else

- Access from any device PC/laptop/Mac/Tablet-no restrictions

- Includes Online Exam and Certification

- Prove your competency by displaying your electronic badge online on social media

- Full fledged e-learning course- Its not a just a Youtube video of a guy speaking, nor a pdf or a PPT, but an interactive course.

- Learn from Real life situations and case studies

Everything that you need to know about Safety Instrumented Systems -in one course!

All the following topics are included. No other course out there covers all of this, at this price! Everything is explained in a very easy to understand manner. Examples from real life situations in manufacturing plants and similar production or storage facilities.

- Introduction & Basic Concepts

- Hazard and Risk Analysis

- Failures & Reliability

- Safety Integrity Level (SIL)

- Safety Instrumented Systems Standards

- How to implement a Safety Instrumented System

- Testing and Maintenance

So what are you waiting for? Get this XPRTU software now, access it online.

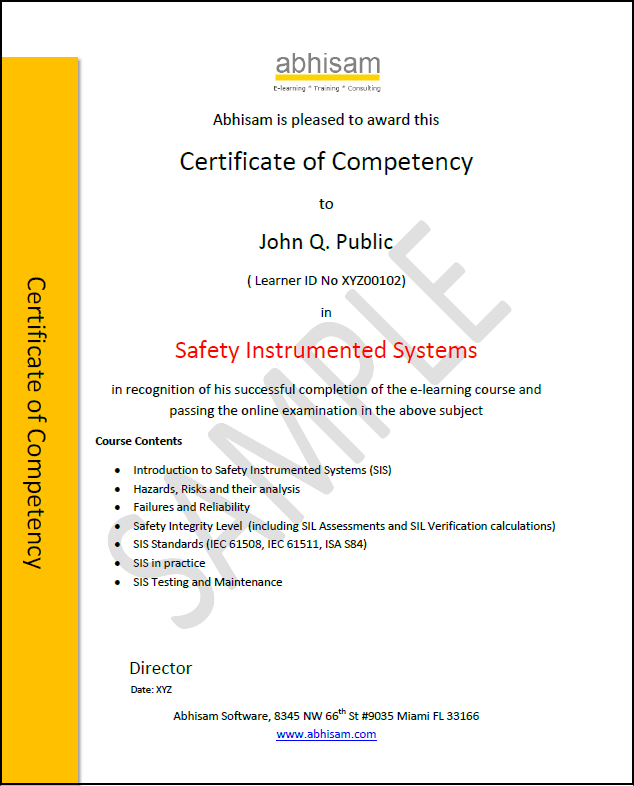

Get Certified as a Safety Instrumented Systems Professional! Earn an electronic badge that you can display online

Customer Reviews

“I have worked in the International Oil and Gas Industry as a technical instructor for more than thirty years. I have both used and recommended the products of Abhisam. I recommend them highly to all engineers and technicians in our industry. No praise is too great!!“

John Longden

GCGI LCGI. Senior Trainer

Petroleum Training Institute, UK

I am working in one of the world’s leading EPC companies, engaged in the Oil & Gas industry. I have purchased the Safety Instrumented Systems, Hazardous Area Instrumentation e-learning courses and Hazardous Area Classification. All of them are excellently crafted, the best available online, with excellent support via email.

I appreciate the good work done by Abhisam and hope that they do come out on more such courses.

D. Jha, Engineers India Ltd

New Delhi, India

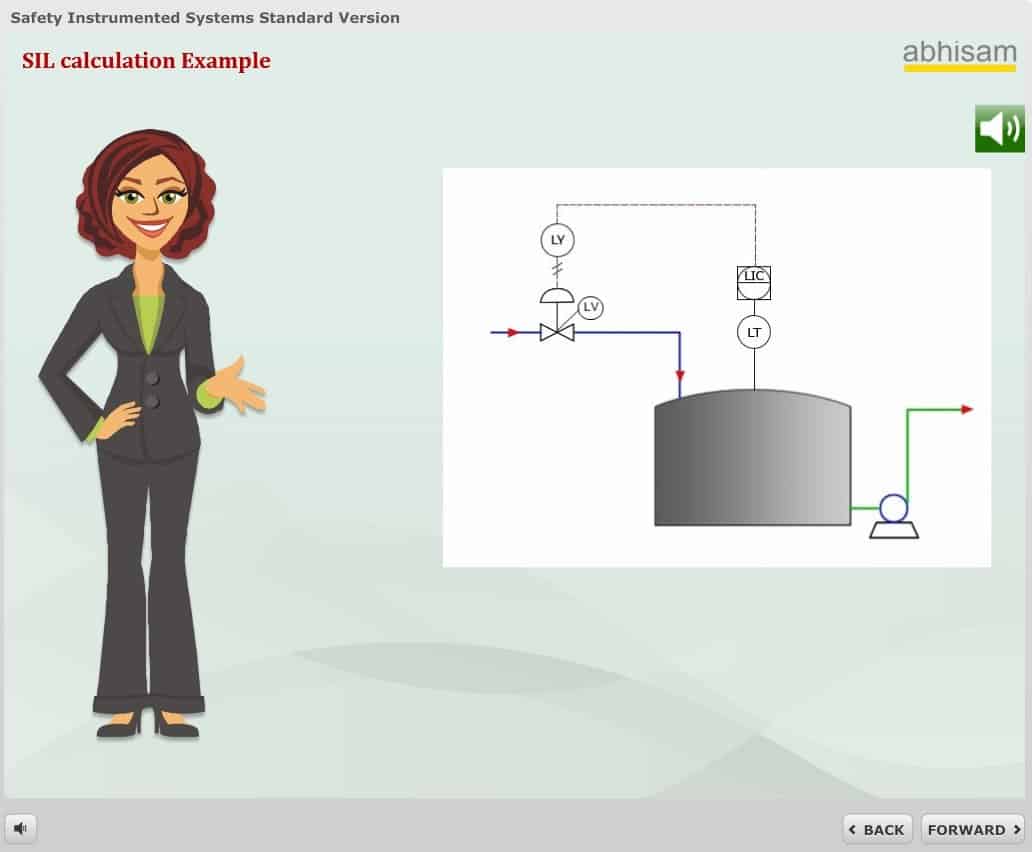

The course has a large number of easy to understand Animations & Simulations to understand difference between process safety and functional safety. Understand how safety instrumented functions work. A picture is worth a thousand words. An animation is worth a thousand pictures. Concepts get understood easily. Compare this to listening to a boring lecture! Below is a small sample of the numerous animations and simulations that you will learn from.

How can I implement a Safety Instrumented System?

This course has plenty of Safety Instrumented Systems examples. Learn how to do a SIL Determination, Design & Verification from actual real life examples. Everything is explained in a Step by Step method, you can use the same methods in your own plant or project to design your safety instrumented functions!

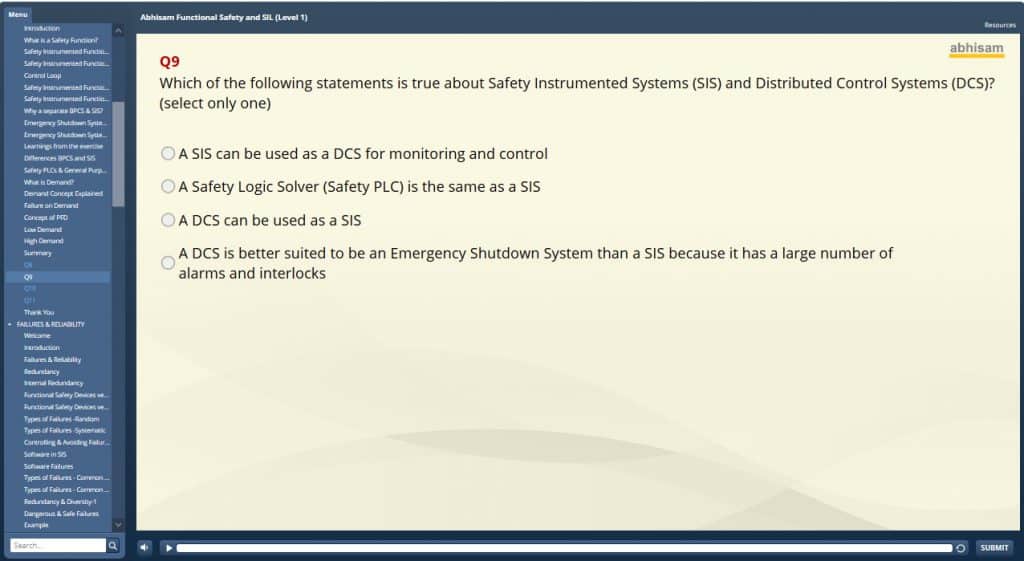

The course has a Self Assessment Test, that helps you gauge your own understanding of the subject. Get immediate feedback on whether you correctly answered the question or not. This also helps you prepare for the online Certification Exam, that you can take & get a Certificate for free!

Learners from leading companies have taken this course and got certified

The Abhisam Safety Instrumented Systems course has been taken by hundreds of learners from all over the world. They work as engineers, managers, executives, trainers and consultants for leading companies around the world. Here’s a sample of the marquee companies who have used this course to train their learners.

Note: All logos belong to their respective owners.

Choose from any of the versions.

Scroll below to see complete contents.Standard

For one learner-

Course Duration: 40 hours of self paced learning (Earn 40 PDH)

-

Access the course online 24/7 via any device for one year

-

Exam & Certification for one learner

-

Lifelong Valid Certificate

Professional

For one learner-

Everything in Standard plus

-

Access course for 3 years

Get Trial Course Access to all Abhisam courses, including this Safety Instrumented Systems course for $7. You will NOT be billed automatically after trial ends.

Table of Contents

Click the + sign to expand

MODULE 1- Introduction to SIS

What are Safety Instrumented Systems?

Basic Ideas about SIS

Functional Safety

Instrumented Systems & Safety Instrumented Systems-1

BPCS (Basic Process Control System)

Basic Process Control System and Safety Instrumented System

Safety Instrumented Function (SIF)

Emergency Shutdown Systems

Need for a separate Safety Instrumented System

Simulation exercise

Learnings from the exercise

Typical architecture (including sensors logic solver and final control element)

Integrated Basic Process Control System & Safety Instrumented System

Examples

Safety PLCs (Safety Logic Solver) & General Purpose Programmable Logic Controllers

BPCS and SIS

Differences between the Basic Process Control System and the Safety Instrumented System

Q1

Q2

Q3

Q4

MODULE 2 – Hazards, Risks & their analysis

Hazards & Risks

Types of hazards- Fire & Explosions

Types of hazards-Toxic Material

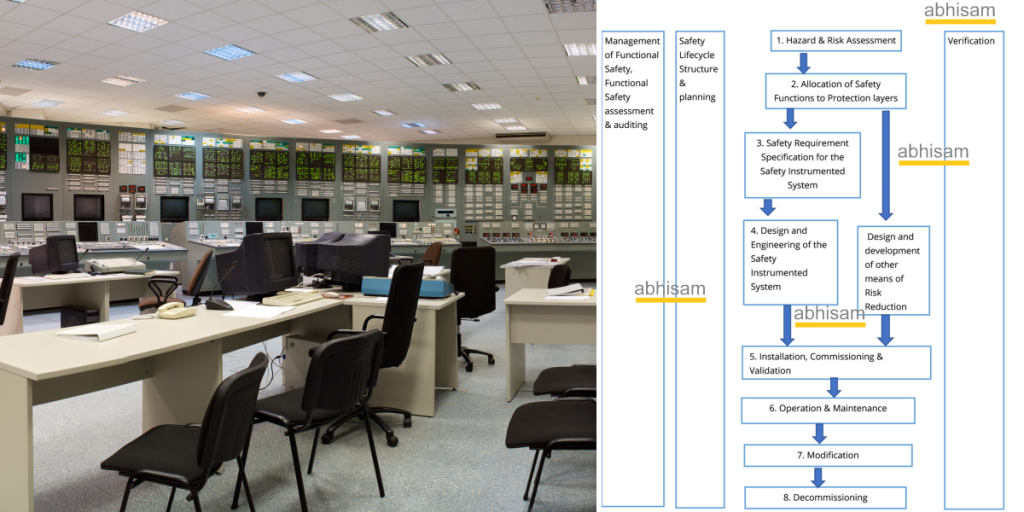

The Safety Lifecycle

Steps in analysis

Preliminary Hazard Analysis

HAZOP

HAZAN

QRA

Consequence Analysis

Risk

Risk Example

Risk Reduction

The ALARP principle

Risk Reduction in process plants

Risk Reduction explained

Risk reduction using a Safety Instrumented Function

Layers of Protection

Layers of Protection in the process industries

Preventive & Mitigative layers

Safety Requirement Specification

SRS Importance

SRS-Minimum Requirements

Q5

Q6

Q7

Q8

MODULE 3 – Failures & Reliability

Failures

Why Study Failures

Types of Failures

Random Failures

Systematic Failures

Random or Systematic

Common Cause Failures

CCF Example

Control of Failures

Avoidance of failures

Diversity

Dangerous & Safe failures

Safety Systems and Subsystems

Safe Failure Fraction

SFF Pie Chart

No Part & No Effect Failures

Easy SFF

SFF calculation example

SFF Manipulation

Proof Test Interval

Diagnostic Coverage

Reliability

Failure Rate

MTTF (Mean Time To Failure)

MTTR (Mean Time to Repair)

MTBF (Mean Time Between Failures)

Failure Data

Software Reliability & Fault injection

Reliability Block Diagrams

Redundancy and Reliability

Fault Tree Analysis

Fault Tree Analysis Example-1

FTA and RBD

Fault Tree Analysis Example-2

Fault Tree Analysis – Probabilities

Event Trees

Event Tree Components

Event Tree Analysis Example

Fail – Safe and Fail Danger modes

Failure Modes Effects and Diagnostic Analysis

FMEDA & Reports

How to use the FMEDA report

Example FMEDA report

Redundancy

Redundancy and Voting

Voting Systems 1oo1

Voting Systems 1oo2

Voting Systems 1oo2D

Voting Systems 2oo2

Voting Systems 2oo3

Spurious Trips

Concept of Demand

Demand in a plant

Low Demand & High Demand

Continuous Demand

PFD

PFDavg

Q9

Q10

Q11

Q12

MODULE 4 – Safety Integrity Level

Introduction to Safety Integrity Levels

What is a Safety Integrity Level (SIL)?

What SIL is not

Safety Integerity Levels -SIL 1 to SIL 4

Is SIL applicable to me?

SIL Study

SIL for Demand Mode

SIL Caveat

Low Demand Mode

Safety Integrity Levels for Continuous / High Demand Mode

- SIL Table for High Demand and Low Demand Modes

The Safety Integrity Level process

Common SIL Questions

Systematic Capability

Concept of Element

Systematic Capability Synthesis

Synthesis of elements

Achieving Systematic Capability

Architectural Constraints

Introduction to Architectural Constraints

Target SIL-Qualitative & Quantitative methods

Risk Reduction Factor

Safety Availability and PFDavg

SIL calculation Example

SIL 4

Consequence Only Method

Hazard Matrix Method

Hazard Matrix Method – Example

Risk Parameter Graph

Calibrated Risk Graph

LOPA

Conducting a LOPA

LOPA Method

More about LOPA

LOPA Example

Target SIL & SIL verification

SIF design process

PFD of a simple loop

SIL verification example – 1

PFDavg-Complex Loops

Markov Modeling

Simplified Equations

Use of Simplified Equations

Architectural Constraints

Hardware Fault Tolerance

Type A subsystems

Type B subsystems

Which Architectural Constraints to follow?

Hardware Fault Tolerance – IEC61508

Architectural Constraints-IEC 61508

Architectural Constraints – Example

Architectural Constraints – IEC61511

Architectural Constraints- IEC 61511 Ed 2

Use IEC 61508 or IEC 61511 Constraints?

Proven in Use

Proven in Use & Prior Use

HFT example

Verification Calculation Procedure

Series and Parallel Architecture

Resolving a Series Parallel Architecture- Example

Verification Calc Example

Conclusion

Q13

Q14

Q15

MODULE 5 – SIS Standards

Introduction to Standards in SIS

AK 1 to AK 8

International Electrotechnical Commission Standards

IEC 61508

IEC 61508:2010

E/E/PE systems

Safety Lifecycle

IEC 61508-Safety Life Cycle

IEC 61511 – Basics

Relationship between IEC 61508 & IEC 61511

Which standard do I follow?

Certified Devices

Revisions-IEC 61508

No Part & No Effect

Architectural Constraints

Security

ISA S84 Background

ISA S84 Differences

IEC 61511

Functional Safety Management

Where to get standards

What standards apply to me?

Conclusion

Q16

Q17

Q18

Module 6-SIS in practice

Components of the Safety Loop

Types of logic Solvers

Hardwired logic solvers – Trip amplifiers

Hardwired logic solvers – Gates

Safety Relays – Electromechanical

Safety Relays – Electronic

Programmable Logic Solvers

Safety PLCs & General Purpose PLCs

Safety PLC Design Techniques

Safety PLCs & General Purpose PLCs

Fault Diagnostics

Safety Logic Solvers-Inputs

Safety Logic Solver-Processors

Safety Logic Solver-Outputs

Safety Logic Solver-Software

Safety Logic Solver-Software-Design

Safety Logic Solver – Voting architecture

Safety Logic Solver – Triple Modular Redundancy(TMR)

Safety Logic Solver – Quad Modular Redundancy(QMR)

Safety Logic Solver Interface to BPCS

Safety Networks

High Integrity Pressure Protection System – HIPPS

Conclusion

Q19

Q20

Q21

MODULE 7 – SIS Testing & Maintenance

Need for testing- Safe State and Unsafe state

Testing – Example

Breakup of failures

Testing the components of a SIS

Testing Sensors & Transmitters

Testing Logic Solvers

Testing valves

Valve Testing – Bypass method

Partial Stroke Testing – 1

Partial Stroke Testing – ISA method

Valve Testing- Mechanical Stoppers

Valve Testing – Smart Positioner method

PST-Advantages & Disadvantages

Testing and PFDavg

Security Assessment

Testing for Stuxnet

Conclusion

Q22

Q23

Q24

Conclusion

A Self assessment Tests is included in the modules.

What are Safety Instrumented and Critical Control Systems? Why are Safety Instrumented Systems important?

These systems help safely shutdown plants in case of emergencies, plant upsets or when the basic industrial automation controls of the plant fail. These systems are the last layer of protection available to a plant, which prevent unwanted incidents.

Companies have realized that negligence (or ignorance), in respect of an instrumented system and especially of a Safety Instrumented System can be really disastrous, literally. Look at just a few recent cases that have been listed below (scroll down to see).

Incident: Caribbean Petroleum, Puerto Rico, 2009– Accident caused due to non working of the overfill protection instruments (part of the Safety Instrumented System). A massive fire and explosion sent huge flames and smoke plumes into the air at the Caribbean Petroleum Corporation near San Juan, Puerto Rico. The resulting pressure wave damaged surrounding buildings and impacted moving vehicles. The final report into the incident was released by the US Chemical Safety Board and it was non working of the overfill protection system (part of the Safety Instrumented System).

Incident: Caribbean Petroleum, Puerto Rico, 2009– Accident caused due to non working of the overfill protection instruments (part of the Safety Instrumented System). A massive fire and explosion sent huge flames and smoke plumes into the air at the Caribbean Petroleum Corporation near San Juan, Puerto Rico. The resulting pressure wave damaged surrounding buildings and impacted moving vehicles. The final report into the incident was released by the US Chemical Safety Board and it was non working of the overfill protection system (part of the Safety Instrumented System).

Morgantown, North Carolina,USA, 2006

Explosion at a polymer manufacturing plant led to total damage of the facility, with a human fatality and several injuries. Investigations found out that a lack of process safety standards and non implementation of automatic interlock systems (in other words, logic solver of the Safety Instrumented Systems) as the root causes of the disaster.

Buncefield, UK, 2005- non working of the Overfill prevention system (part of the Safety Instrumented System)

Buncefield, UK, 2005- non working of the Overfill prevention system (part of the Safety Instrumented System)

The Buncefield industrial disaster was one of the biggest disasters to strike the chemical and petrochemical industry in Europe in recent years. The blasts that occurred were so loud, they were heard as far away as France! (Buncefield is in the UK) The root cause was found out not because of the logic solver but due to a bypassed level switch (part of the Safety Instrumented System) on the site.

To make these systems work for you, you need to know them thoroughly ( We mean not from a programming point of view but from a users point of view). You need to get trained in all the concepts and ideas, including applicable codes and standards, ( including international Standards for safety instrumented systems such as IEC 61508:2010 and IEC 61511:2016, ISA S84) plus good engineering practices of these critical Systems. Note that here, when we refer to such systems, we also include Emergency Shutdown Systems (ESD), Safety Shutdown Systems, High Integrity Pressure Protection Systems (HIPPS) and all similar systems that are used to ensure the safe operation of plant and machinery, using highly reliable instruments, controllers, valves and other electrical and pneumatic/hydraulic elements and devices.

A SIS consists of several safety instrumented functions, also known as SIFs that include sensors, logic solvers and final control elements like actuators, control valves and dampers.

Get immediate access to this easy learning program (that we call an XPRTU-since it makes you into an expert).

Learn everything, take an online exam and get your Certificate of Competency, alongwith an electronic badge that you can display online on places like LinkedIn. It is all included in one low price!

You can simply get access to this e-learning course and learn all about these systems, in the comfort of your home or office, in a very easy to understand manner. Simple and easy to learn, with several interactive animations and simulations, this is a great learning experience.

Just get this interactive, self paced training course today and for a fraction of the price that you would otherwise pay for any other course, learn everything that you wanted to know about it (but didn’t know whom to ask). Note that this course is

NOT a Safety Instrumented Systems PPT

NOT an ebook

NOT a video of a guy speaking

It is a comprehensive, software based learning program that combines interactive animations and simulations, real life examples & situations from real plants and facilities, an explanation of all difficult to understand terms in very easy language, a self assessment test and much more. It is a unique learning experience and we daresay that it is the only such program today in the world.

You can get this excellent, self paced, e-learning software based training course from Abhisam and be assured that

a) You will get instant access within minutes when you click the Buy button below and process your payment

b) You will get an easy learning experience due to the extensive graphics, animations, real life examples and situations, calculations, videos, assessments in the course, which has been created by Abhisam, pioneers and global experts in technical e-learning

c) You can get certified as an Abhisam Safety Instrumented Systems professional at no extra charge with a lifelong valid Certificate . Also earn an electronic badge that you can display online on places such as LinkedIn.

d) Earn Professional Development Hours (40) for this course.

Free SIS information and Whitepapers

Contact Us by filling the form below OR call us OR email