What are Safety Instrumented Systems?

Safety Instrumented Systems are automation systems that kick into action when some deviation from the normal operating parameters has the potential to trigger an unwanted incident. These include both (relatively) simple systems like OPS (overfill prevention systems), that prevent overfilling a storage tank by sensing the high level and automatically stopping the inlet flow on high level, as well as more complex systems such as HIPPS (High Integrity Pressure Protection Systems) that protect equipment from overpressure.

In this post we will now understand why in the case of Safety Instrumented Systems- a Life-cycle approach works best.

Note: To understand SIS in depth and get certified, please take the Abhisam Safety Instrumented Systems course today. This is the easiest, most comprehensive course out there and costs a fraction of the cost that you would pay for similar courses from other providers. Do check it out.

Simply speaking, a SIS automatically brings the plant or equipment to a safe state from a dangerous state. If the Safety Instrumented Systems design does not work, then there is a very high probability that an unwanted event such as a loss of containment or an explosion will occur.

Safety Instrumented Systems can be thought of as a collection of Safety Instrumented Functions (or Safety Loops as some people prefer to call them). These SIFs together are referred to as the SIS. Thus a SIS is not a single monolithic device, but rather a collection of somewhat separate SIFs. Every SIF has at least one sensor/transmitter, a logic solver and a final element that carry out a safety function. The safety function has to be carried out reliably, within the process safety time, whenever it is demanded to do so. Thus in the above overfill prevention system, if the level goes very high, then the SIF comes into the picture (a demand is generated) and the SIF carries out the function on this demand by shutting off the inlet flow and preventing spillage from the tank.

What does having Safety Instrumented Systems a Life- Cycle approach mean?

The Safety Life cycle is an important concept that must be understood clearly. It recognizes that “Safety” is not like a standard product or service that one gets out of the box, but rather that it is the result of a process which is closely integrated with the lifecycle of the process plant that it protects.

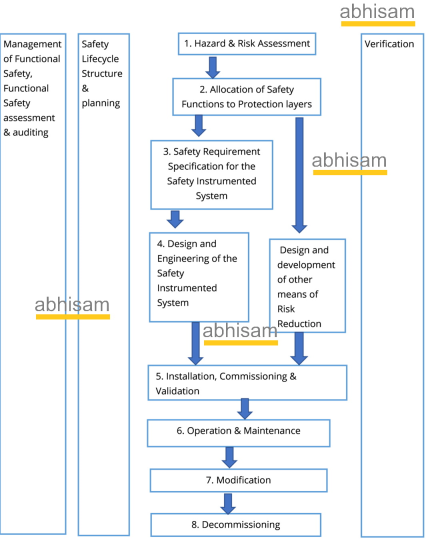

The picture shows the Safety Life-cycle, as outlined in the well accepted IEC 61511 standard (ISA S84 in the United States), which is the currently accepted standard all over the world for Functional Safety in the Process Industry. Process industries are those where bulk materials get processed rather than discrete parts. Examples are industries such as Oil and Gas, Petroleum Refining, Chemicals manufacturing, Pharmaceutical APIs, Pulp & Paper and similar.

The different parts of the Safety Life Cycle are called as “phases”.

Why when using Safety Instrumented Systems a life-cycle approach makes sense

Any process plant has a lifecycle that starts from the day the plant is conceptualized in the minds of the owners and ends at the time that it is decommissioned, dismantled and the residual assets disposed off as scrap. This timeline can be very long, typical plant lifetimes can be as long as 50 years.

During this time, it is not static. Perhaps new equipment gets added, old equipment may be removed or modified, the process may change. During all these changes the SIS has to continue its mission of protecting the plant from unwanted incidents. Hence the SIS is also evolving in tune with the plant.

If it does not, then it may no longer meet it’s raison d’etre (reason to exist). Hence in order to be useful, the SIS must also evolve along with the plant that it protects.

Let us now see the various phases of the Safety Life Cycle.

The Safety Life Cycle

Hazard and Risk Assessment

In this phase the different kinds of hazards in the plant or equipment are identified and risk assessment carried out. We may use different Process Hazard Analysis (PHA) techniques such as HAZOP and What-If analysis. Furthernore, we can also carry out a LOPA (Layer of Protection Analysis) for getting a more quantitative analysis of the risk. Abhisam has courses on all of these and you can access all of these when you become a GOLD Member.

Allocation of Safety Functions to Protection Layers

In this phase the different SIFs are allocated to the different protection layers. If you carried out a LOPA then this is done during the LOPA sessions.

Safety Requirement Specification (SRS)

This is one of the most important phases in the Safety Life cycle. This where the owner/operator and the designers of the SIS sit down and decide what they want as part of the Safety System. This SRS may comprise of a Hardware SRS, a Software SRS and should have have SIS cyber security requirements. The Abhisam SIS Course covers this in great detail.

Design and Engineering of the Safety Instrumented System

This phase is where each SIF is designed by selecting sensors, transmitters, logic solvers, final control elements and other related components such as signal conditioners, Intrinsically safe barriers, pushbuttons, safety relays and switches. This design will be as per the SRS.

Other means of Risk Reduction

The SIS is just one of the ways in which we can protect the plant. There should be other protection layers too, such as dike walls for tanks, flares, scrubbers, safety relief valves, burst disks, etc. This phase shows that at this point of time we should start design and engineering of these other means of risk reduction also, in addition to the SIS.

Installation, Commissioning and Validation

In this phase the Safety Instrumented System will be installed (along with the plant and equipment) and commissioned. When we conduct trials to check whether everything works as designed, it is known as “Validation”. If the system does not work, then we have to go back to modification, change management and so on depending on the root cause found.

Operation & Maintenance

This is one of the longest running phase because the plant may run for something like 50 years. During this time the SIS has to be tested regularly, maintained and repaired in case of any failures. Everything has to be recorded in a database, so that the true failure rates can be assessed.

Modification

Any plant will have some or the other modifications that need to be done due to process changes, new environmental regulations, replacement of equipment, capacity increases or product changes. There are rules laid out in the standard for carrying out modifications, one cannot just change anything.There are for example Management of Change (MOC) and other procedures to be followed.

Decommissioning and Dismantling

After many years of operations, sometimes a plant becomes too old and obsolete, or maybe the environmental laws became more stringent, due to which it cannot operate any longer. At this stage, the plant is decommissioned and dismantled. This also has a lot of activities to be done, so that the process is carried out in a safe manner without causing any harm to people or the environment.

Functional Safety Management

During this entire lifecycle. the management of functional safety has to work well.Thus Functional Safety Management is very important. You can learn more about Functional Safety management in the Abhisam Functional Safety and SIL Courses (Level 1 and 2), as well as in the Safety Instrumented Systems course.

Verification

Unlike popular belief, verification is not checking the PFDavg calculations only. Rather, it is applicable for every phase of the lifecycle, according to the IEC 61511 standard. It is to be done by an independent person, department or entity. You cannot verify your own work.

Where can I learn more?

You can learn in detail about Functional Safety and Safety Instrumented Systems when you take the Abhisam courses today. All Abhisam courses are online, self paced, flexible elearning software based courses that you can access from anywhere in the world whenever you wish via any device including PCs, Macs, smartphones or tablets. This way, you can become a certified Functional Safety Professional at a much lower cost and much more easily rather than attending a live class and being under pressure for 4-5 days of continuous training followed by the exam. The Abhisam exam you can take anytime that you wish.