A Safety Instrumented System (SIS for short) is used in many process plants to ensure continued safe operation of the process. In case of any disturbance that is likely to result in an unwanted incident the SIS automatically brings the process to a safe state and prevents loss of life, asset damage and environmental damage. For process plants that handle hazardous, toxic, explosive or other similar materials, Safety Instrumented Systems prevent unwanted incidents from happening.

What is a Safety Instrumented System?

In an earlier tutorial, we explained what a Safety Instrumented Function (SIF for short) does. In case you have not read it, we encourage you to do that now.

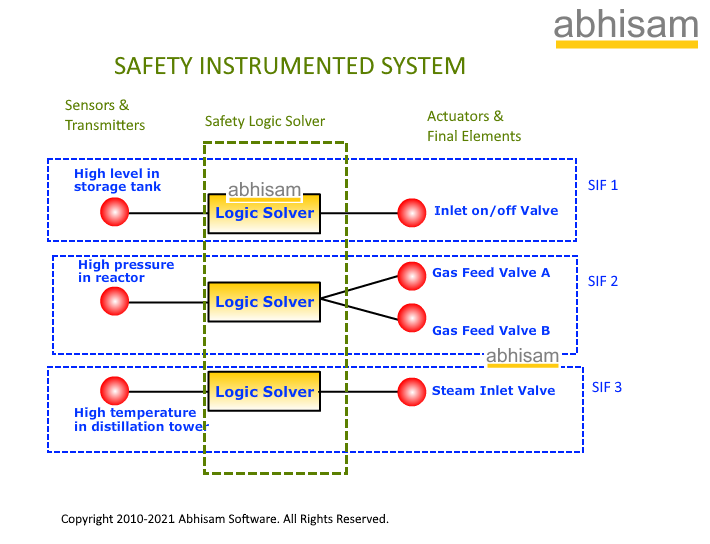

A Safety Instrumented System can be thought of simply as a collection of Safety Instrumented Functions.

Take a look at the diagram shown here. It shows three Safety Instrumented Functions (SIF1, SIF 2 and SIF 3). All of these safety instrumented functions share a common logic solver, which is colloquially referred to as a “Safety PLC”. We call it as a Safety Logic Solver.

If these are the only three functions in that plant, then these three together constitute the Safety Instrumented System.

Are you sure? What is then a Safety PLC? Is it not a Safety Instrumented System?

If a programmable logic solver is used in a Safety Instrumented Function, then oftentimes it is referred to as a “Safety PLC”. However, this term is not generally used by professionals, who refer to this device as simply a “Safety Logic Solver”, or just “Logic Solver”. This is because it is just one of the components used in a Safety Instrumented System, it is not by itself the SIS.

Also remember that a logic solver need not be programmable, it can be also of analog electronic design or even hardwired using relays or any combination of these components.

At the same time, it is not a good idea to use an ordinary industrial PLC for this purpose, because most probably it has not been designed for use in a Safety system. As explained below, it should be designed according to the guidelines given in the international standard IEC 61508.

So what is a Safety Instrumented System?

As explained earlier, it is a collection of Safety Instrumented Functions. As you know by now, a SIF consists at the bare minimum- a sensor, logic solver and actuator. In many plants, the logic solver is common among many SIFs. Many times it is the most expensive part of the SIFs , so it gets a lot of attention.

However, it is of no use to have a sophisticated, expensive logic solver and use ordinary sensors and actuators to implement the safety function. The field devices need to be very reliable and robust, designed to be used in a Safety Instrumented System and must survive harsh conditions in the field including weather, possibly a corrosive atmosphere and other sub optimal conditions.

What about certified devices and Safety Instrumented Systems?

Any device which is to be used in a SIF should conform to the International Standard IEC 61508. This ensures that the device is designed in a way that its reliability is very high. For the process industry, the definitive and well accepted standard for Safety Instrumented Systems is IEC 61511 (ISA S84 in the US). The SIF as a whole should conform to IEC 61511 and the individual devices should conform to IEC 61508.

For the end user or system integrator, evaluating such devices in detail with reference to the standard is a very time consuming exercise, so we have several third party certification companies who do just this and issue a certificate that says that the device conforms to IEC 61508 (possibly with a lot of caveats). Bear in mind that this is for convenience and the end user has to ensure that the device will perform well in their particular conditions. Merely using certified devices does not automatically guarantee anything. Hence the term”certified devices” does not appear in any of these standards.

Note: Enter your Contact Information below if you wish to get this free guide (form below). Scroll below to continue reading.

How can I build my SIS?

As you must have guessed by now, building a Safety Instrumented System is not a simple task. Building a new SIS involves activities such as Specifying, Designing, Engineering, Installing, Testing,Commissioning, Validation of the SIS. These activities are part of a lifecycle, that is in sync with the lifecycle of the plant (or equipment) that the SIS protects.

You can have either an integrated SIS DCS or a separate DCS and SIS, both options have their advantages and disadvantages.

Where can I know more about SIS?

You can take our excellent Abhisam online Safety Instrumented Systems training course. Not only will you learn everything in great detail, you can take the associated exam and earn a Certificate of Competency in SIS, as well as an electronic badge of Abhisam SIS Professional.